The Cooling Companion

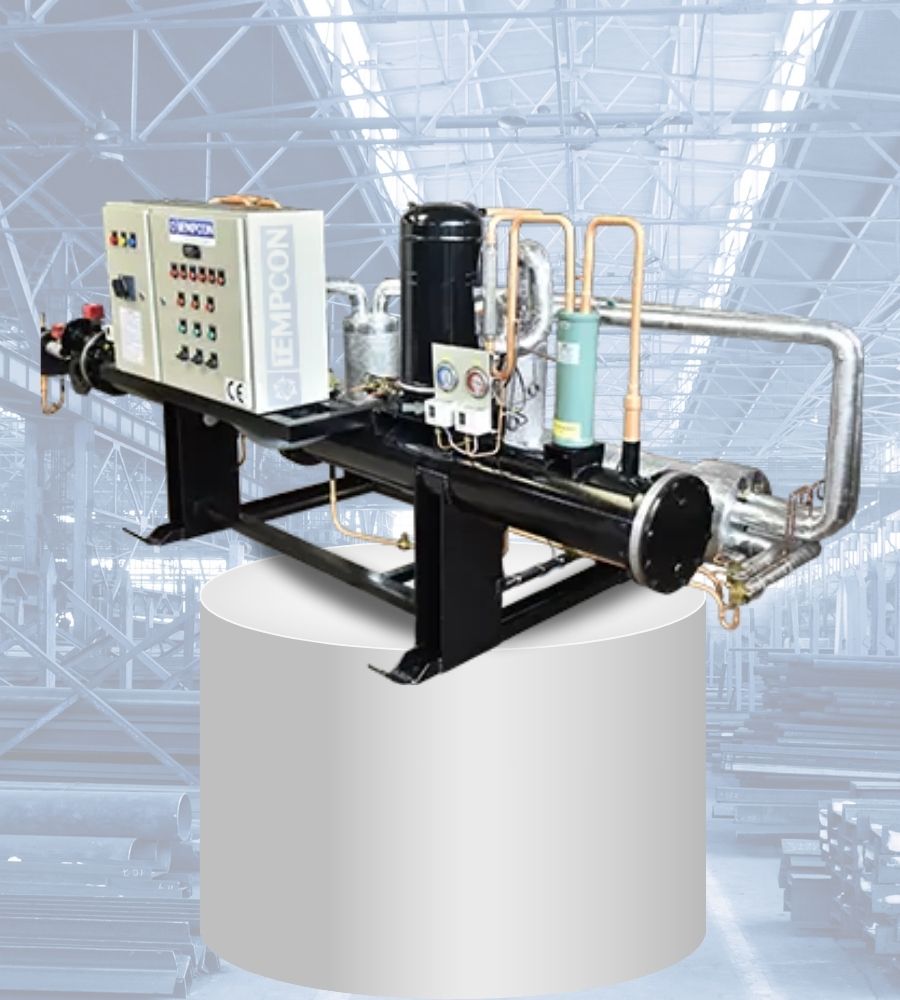

Chillers For Concrete Batching

Concrete batch plants require precise temperature control to provide high-quality concrete mix in all weather conditions. A water chiller provides the right temperature of water to produce concrete and manage its quality all year round.

Tempcon has brought to you the perfect range of industrial water chillers for concrete batch plants to install on the premises. Maintain optimal concrete mix temperature during hot summer months.

Designed Specifically for Concrete Batch Plants

Our industrial water chillers are designed to meet the specific requirements of concrete batch-processing units.

Heavy-duty Durable Construction

Epoxy powder coated galvanized steel frames to protect chillers from dust, moisture, and harsh environmental conditions

High Cooling Capacity

Our chillers offer a wide range of cooling capacity, befitting the needs of small to large concrete batch plants.

Simple Control Systems

User-friendly human-machine interface with a touchscreen to control cooling parameters. Plant operators can easily monitor and change chilling requirements.

Reliable Performance

Chillers with UL and CE-certified components offer continuous service, irrespective of the ambient temperature conditions.

Technical Specifications of Water Chillers for Concrete Cooling

Cooling Capacity: 5TR to 250TR options available – sized to match your batch plant production volume

Temperature Range: Capable of maintaining water at a specified temperature range

Compressor Types: Scroll or screw compressors – selected based on plant size and operational hours

Condenser Options: Air-cooled or water-cooled configurations – adaptable to your facility’s infrastructure

Control System: Microprocessor control with digital display to track water temperature

Refrigrant: Eco-friendly R134a, R407C, or R410A options – compliant with environmental regulations

Pump System: High-pressure stainless steel centrifugal pumps – resists corrosion from treated water

Decades of expertise in industrial cooling solutions

Chillers designed specifically for concrete production requirements

For ultimate safety, reliability and efficient operations

Eco

Hear From Our Clients

Thanks Sourav dasmondal and thanks Tempcon

Also the after sales service is very good.

FAQ

How does an industrial water chiller improve concrete quality?

How can I determine the size of the water chiller for my concrete batch plant?

Is there a way to save on electricity bills while using industrial water chillers?

Do water chillers require special maintenance in dusty concrete batch plants?

Ready to Optimize Your Concrete Production? Contact Us Today!

Get in touch with us for a free consultation and custom quote.

FAQ

Yes. Our industrial water chillers are designed to operate non-stop without compromising cooling output. These chillers can run in any industrial and climatic conditions

It depends on the type of water tank chiller you have chosen to install. However, our experts analyze the specific requirements and then decide on the cooling capacity. It avoids overloading and underperforming circumstances to keep the chillers performing better. Apart from the precautionary measures, we offer maintenance services during the warranty period and extend it based on a service fee as per your choice.

It depends on the type of chiller, tonnage, and industrial premise orientations. However, once the chiller design and tonnage are decided, it takes only 4 weeks to deploy the infrastructure to the industrial site.

We resolve common industrial chiller issues by calls. If the problem is not solved on the phone, we send a team of trained local engineers to look into the matter and solve the issues as early as possible. Our prime motive is to reduce downtime and keep your industrial setup running at its peak.