In-Warranty Service

We have designed our in-warranty service package to include three free warranty services. It is our duty to ensure that the equipment is giving an optimum output as promised.

Comprehensive AMC

Our AMC offers extended warranty coverage for the major modular components of industrial chillers we have installed.

Non-Comprehensive AMC

Keep your industrial chillers in top condition for all seasons with Tempcon’s non-comprehensive annual maintenance contract (AMC).

Tempcon’s On-Call Service

We provide on-call maintenance and repair service for your industrial chillers. There is no need to sign an annual contract.

Tempcon’s Refurbishment Service

Breathe new life into your ageing industrial chillers with our refurbishment service. Our expert technicians will inspect the chillers and identify areas for upgrades and refurbishments.

Scrap Disposal and Buyback

We offer scrap disposal and buyback services to get rid of your old industrial chillers. In exchange, get competitive rates for the scraps or a special discount on new Tempcon’s industrial chillers.

The Cooling Companion

Tempcon Annual Maintenance Contract

Many industrialists make a common mistake – not hiring the manufacturing agency to maintain the product. The company is more aware of which parts cause what errors than any third-party maintenance crew you could hire.

The local crew might not even have the suitable instruments and products required for the repairs. So it’s best to get the service directly from the parent company.

Do you even need the annual maintenance contract?

Yes, you do. Don’t make the mistake of thinking we will do the repairs when we encounter any issues. Remember, prevention is always better than cure. By spending a minimal amount on annual services, you will save a lump sum for repairs.

Most damages aren’t visible until they cause an extensive machine breakdown. But regular checkups will help detect these damages in the early stages or sometimes even before they happen. And that is why you need the annual maintenance contract.

Why is Chiller Maintenance Necessary?

Condenser

When dust accumulates on the condensers, it restricts airflow. It results in a loss of chiller cooling capacity. That’s why routine cleaning is necessary.

Heat exchanger

Heat exchanger failure can cause production losses and unplanned downtime. Industrial processes generate significant amounts of heat, which can also cause damage to other sensitive equipment.

Pump

Corrosion in the pump can cause it to lose its pumping ability, which will cause fluctuations in the system pressure. The corroded material could also contaminate the refrigerant and cause it to lose its cooling capacity.

Prevent Machine Breakdown

If they go unnoticed, all such things can cause serious machine breakdowns. We have encountered cases where the chillers were beyond salvageable due to years of negligence or improper treatment.

Register for the Tempcon Annual Maintenance Contract (AMC) for:

Improved equipment operation & reliability

Extended equipment life

Reduced operating costs

Reduced equipment downtime

Reduced risks of costly breakdowns

The Tempcon Promise

Key Benefits of Tempcon AMC Services

Servicing, overhauling, and cleaning machines regularly.

Periodic preventive maintenance which can protect the machine from future breakdowns.

Online technical support from experienced service engineers in case of emergency.

Availability of service support at short notice.

Authenticity of spare parts used to replace old machine parts.

Call us

+91 8777366568

+91 7439482790

What’s Included In Tempcon AMC Service?

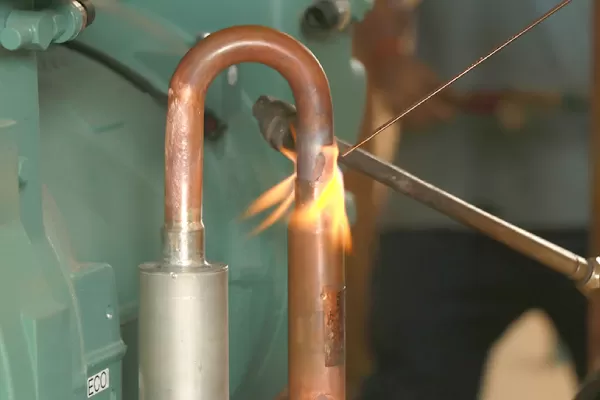

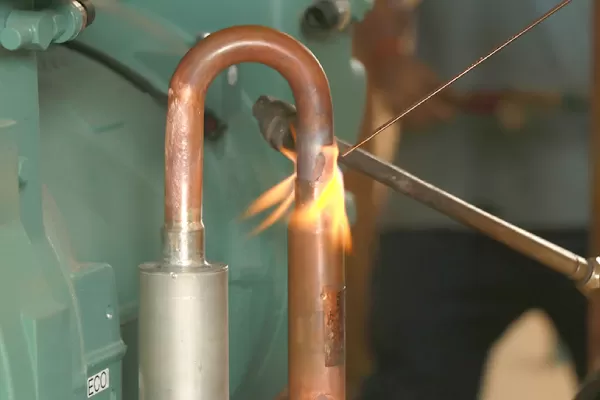

We check for leakages in pipework.

We ensure there are no spills of refrigerant, oil, or water.

We check fixings and fastenings and tighten them when necessary.

We pay special attention to electrical connections and restore any if damaged.

We check the cooling coil fins for distortion and traces of corrosion.

We check the condenser and its bearings for smooth performance.

Read Our Blog Posts

Insights

Chiller Inspection Checklist – What Do We Check When We Go For a Planned Maintenance Visit

The One-Stop Guide to Data Center Cooling: Keeping Your IT Infrastructure Chill

COP29 and the Future of the HVAC&R Industry: Challenges and Opportunities in Sustainable Cooling

FAQ

Tempcon AMC is a service plan that ensures your industrial chillers are maintained regularly by expert engineers from the manufacturer. It includes preventive maintenance, servicing, and cleaning to keep your equipment running smoothly and efficiently.

Tempcon engineers have in-depth knowledge of the equipment and use authentic spare parts, ensuring high-quality maintenance. Local crews may lack specialized tools and expertise, which can lead to improper repairs or overlooked issues.

Yes, AMCs are essential even if your equipment seems to work fine. Regular checkups help detect hidden issues early, preventing costly breakdowns and extending the lifespan of your chiller.

By choosing Tempcon AMC, you gain:

- Improved reliability

- Extended equipment life

- Cost savings

- Minimal downtime

- Genuine parts

These benefits ensure your chiller operates at peak efficiency year-round.

Yes. Regular servicing ensures that components like condensers, pumps, and heat exchangers are clean, free from corrosion, and functioning optimally. Preventive maintenance detects and addresses minor issues before they escalate. This step ensures consistent cooling efficiency, reduced energy consumption, and extended equipment life.