The Cooling Companion

Chiller Units For Precision Cooling

We understand how important a chiller unit is for an industrial setup. This is why we pour our four decades of experience and the latest technology to create the best chiller solutions to meet your needs.

Our range of industrial chilling units combines state-of-the-art CE and UL-certified components to handle heavy operational loads intelligently to reduce energy usage by up to 35%. For that, we offer a turnkey solution from choosing the best option to installing it on your site.

Types of Industrial Chiller Units We Offer

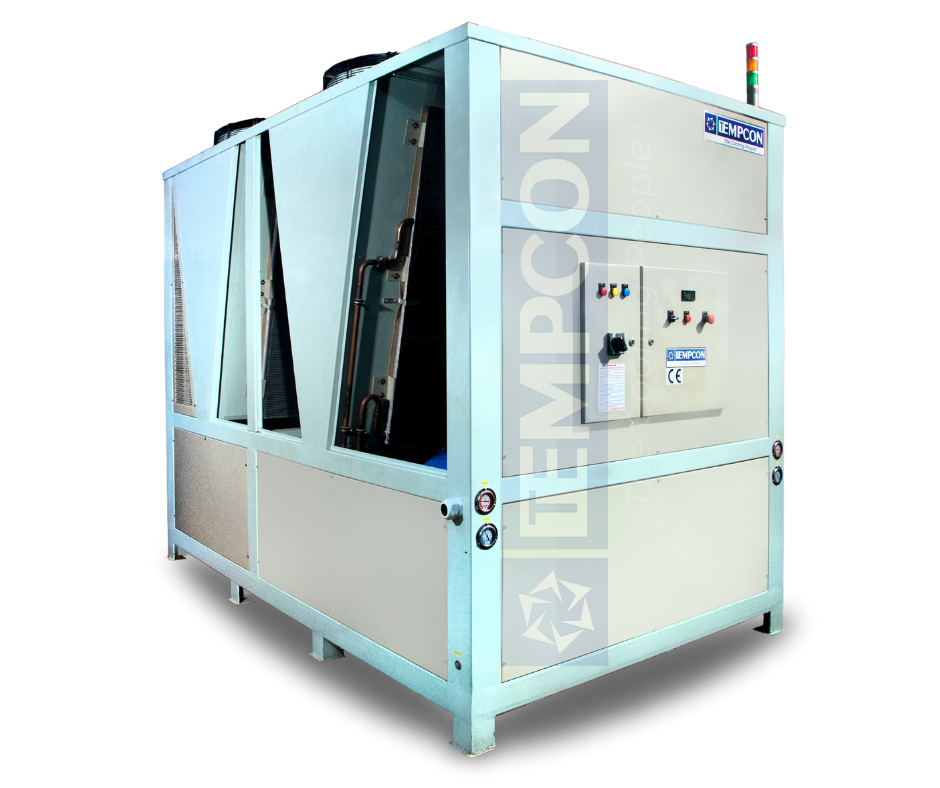

Air-Cooled Scroll Chiller Units

Our industrial air-cooled scroll chiller units combine affordability with durability for various industrial processes. These units utilize advanced scroll compression technology to offer a cooling capacity ranging from 3 to 80 TR. They feature two low-noise spiral scrolls.

Key Features:

Durable Construction

Galvanized steel structure with epoxy powder coating IP-54 body

Quiet Operation

Hermetic scroll compressors for minimal operational noise

Fan Options

Available with either AC fans (A-version) or energy-efficient EC fans (B-version)

Condenser Options

Choice of copper fin tube condensers or coated aluminium microchannel condensers (reducing refrigerant charge by 30%)

Smart Controls

HMI-based interface with analog controls and remote operation capability

Energy Savings

Optional VFD controllers available for up to 30% energy savings

Air-Cooled Screw Chiller Units

Our air-cooled screw chiller units are designed for continuous operation and maximum energy efficiency. They provide cooling capacities between 50TR and 250TR. The advanced screw compressor technology offers non-stop operation without cycling off.

Key Features:

Industrial Durability

MS body with epoxy-polyester paint

Stepless Capacity Control

Semi-hermetic screw compressor

Customizable Fan Options

EC brushless or axial blow types

Modular Condenser

Air-cooled fin tube with sub-cooling circuit

Energy Efficient

Micro-channel heat exchanger (15% reduction)

Advanced Control

PLC with touchscreen HMI

Easy Monitoring

Shell and tube evaporator

Eco-Friendly Refrigerants

R134a, R407C or R410A

Water-Cooled Scroll Chiller Units

Our water-cooled scroll chiller units are ideal for noise-sensitive environments. They offer quiet cooling operations for both indoor and outdoor usage. These units provide cooling capacities from 11TR to 100TR.

Key Features:

Industrial Durability

Galvanized steel frame with epoxy-polyester powder coating

Quiet Operation

Highly efficient scroll compressors offer a whisper-quiet operation

Efficient Condenser

High-efficiency water-cooled shell & tube condenser

Reliable Evaporator

Shell & tube evaporator for reliable heat transfer

Rust Prevention

Stainless steel centrifugal pump and tank preventing rust formation

Advanced Control

Microprocessor control panel with IP54 electric panel

Certified Compliance

CE certification and compliance with ECO Design Directive

Optional Storage

Optional stainless steel storage tank

Water-Cooled Screw Chiller Units

Our water-cooled screw chiller units utilize the latest refrigeration technologies. They are designed for industrial processes requiring high cooling capacity (60TR to 350TR). These units deliver exceptional efficiency, flexibility, and reliability.

Key Features:

Industrial Durability

Strong galvanized steel frame with epoxy-polyester powder coating

Efficient Compressor

Semi-hermetic screw compressors using R134a refrigerant

Effective Condenser

Shell & tube condenser design for efficient heat rejection

Accessible Evaporator

Specially engineered shell & tube evaporator for easy inspection

Optimal Performance

High-pressure stainless steel pumps for optimal performance

Advanced Control

Advanced microprocessor control panel with electronic expansion valve

Certified Compliance

CE and PED certification with ECO Design Directive compliance

Specialized Chilling Units

Our product line extends beyond standard solutions to include specialized units

Application Areas

Tempcon Air-Cooled Scroll chillers can be used across diverse industries

Plastic Manufacturing:

Maintains mold temperatures for dimensional accuracy in injection molding and prevents warping in blow molding processes.

Food & Beverage Production:

Controls temperatures for pasteurization, fermentation, and carbonation while preventing product degradation.

Oil & Hydraulic Systems:

Prevents overheating in power transmission systems and maintains optimal machining conditions in CNC equipment.

Aerospace & Defense:

Provides precise cooling for materials testing and supports specialized equipment operation.

Renewable Energy:

Regulates production process temperatures for solar panel manufacturing and other green technologies.

Pharmaceutical Industry:

Ensures chemical stability during API production and maintains precise temperatures for laboratory testing and development.

Metal Processing:

Regulates temperatures for aluminium extrusion, electroplating, galvanizing, and surface treatment processes.

Construction Materials:

Controls water temperature for concrete mixing and ensures consistent properties in pipe extrusion and composite materials.

Medical Equipment:

Maintains critical temperatures for devices like MRI machines with superconducting magnets.

Electronics Manufacturing:

Controls thermal conditions during circuit board production and component assembly processes.

The Tempcon Promise

We Assist You in Choosing the Right Industrial Chiller Unit

Our decades of experience and knowledge of the latest industrial chilling trends will assist you in making the right decision. Make us your industrial chiller partner, and let us give you the best and affordable solution.

Our experts visit sites, calculate the cooling capacity required for your unit, and install the right chiller unit in no time. We offer maintenance and repair services, too.

Call us

+91 33 24426216

+91 33 24422359