Chiller Inspection Checklist

Essential checkpoints for planned maintenance

Tracking daily chiller operations is a battle half won. Follow this comprehensive checklist to inspect your chillers effectively and avoid costly repairs.

Inspection Progress

0% Complete

A chiller works efficiently when its modular components are aligned. Like all machines and equipment, industrial chillers face wear and tear. What should you do to prevent major downtime or inefficient chiller outputs? Worry not, as we have prepared a chiller inspection checklist for you to follow.

Why Do You Need a Chiller Inspection Checklist?

A chiller inspection checklist makes sure that your unit runs smoothly and doesn’t break down during peak months. A simple checklist can benefit you by:

Preventing sudden breakdowns by spotting small issues early

Improving energy efficiency to stop overwork or power wastage

Extending chiller

lifespan

Maintaining industry safety by checking for leaks, faulty wiring, or worn components

Helping stay compliant with safety and maintenance standards

Saving money by avoiding costly repairs or replacements

So, what are the things to be included in a checklist? You will need a log sheet to include the checkpoints and serve the chiller maintenance scope of work.

Why Do You Need a Chiller Inspection Checklist?

A chiller inspection checklist makes sure that your unit runs smoothly and doesn’t break down during peak months. A simple checklist can benefit you by:

- Preventing sudden breakdowns by spotting small issues early

- Improving energy efficiency to stop overwork or power wastage

- Extending chiller lifespan

- Maintaining industry safety by checking for leaks, faulty wiring, or worn components

- Helping stay compliant with safety and maintenance standards

- Saving money by avoiding costly repairs or replacements

So, what are the things to be included in a checklist? You will need a log sheet to include the checkpoints and serve the chiller maintenance scope of work.

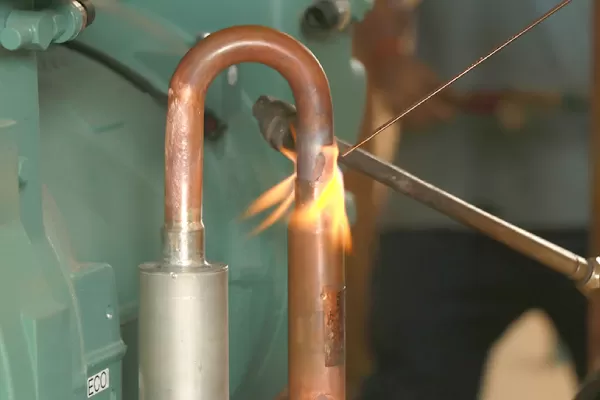

Refrigerant and Oil Checks

- Check refrigerant levels using sight-glasses. Low levels can reduce cooling efficiency.

- Check for refrigerant leaks and signs of contamination.

- Measure oil levels and inspect oil filters.

- Conduct oil analysis to check for contamination. Replace or refill oil if needed.

Evaporator and Condenser

- Check water flow through the evaporator to ensure it’s not blocked.

- Measure evaporator water temperature difference to confirm proper heat exchange.

- Inspect the condenser and evaporator for pressure levels and check controls.

- Check for signs of corrosion, fin damage, or dirt buildup on coils.

- Inspecting for fouling, especially if using open-circuit cooling towers.

Compressor Unit

- Inspect compressor motor operation and efficiency.

- Check the motor voltage and current.

- Check compressor alignment.

- Inspect crankcase heater and suction filters.

- Check for oil, refrigerant, or water leaks.

Fans and Air Handling

- Inspect fan controls and speed controllers.

- Check the condenser fan motor voltage/current where applicable.

- Inspect fan bearings and blade rotations.

- Listen for abnormal fan sounds or vibrations.

- Check fan belts and sheaves for tension and alignment.

Control Systems

- Test all safety control settings and verify they are working.

- Check operating control settings.

- Verify cap control and cap tube condition.

- Check low/high pressure settings and oil pressure readings.

- Inspecting condenser and evaporator control systems (air and water-based).

Electrical Components

- Inspect electrical starters, relays, and contractors.

- Check voltages, amps, and transformer outputs.

- Inspect low-voltage circuits and sensor readings.

- Ensure electrical terminals and connections are tight.

- Confirm the unit is grounded properly.

Visual and Structural Checks

- Look for visible leaks or damaged insulation.

- Check all fasteners, bolts, and fixings.

- Inspecting unit structure and mountings.

- Ensure no abnormal noise or vibration.

- Disconnect the power before any deep maintenance.

Consumables and Fluids

- Test water and glycol quality; check chemical balance to prevent corrosion.

- Replace glycol if concentration is too low or contaminated.

- Check for non-condensables in the refrigerant circuit and purge if needed.

How to Act On Chiller Inspection Findings?

Once a chiller inspection is done, record the findings and compare them with the original system setup provided by your industrial chiller service manufacturer. This comparison helps you spot any changes in performance or if anything is off.

Check the manufacturer’s manual to resolve the issues. If the problems persist, get in touch with the manufacturer’s customer support and seek professional assistance.

Further Reading: Chiller Safety Checklist

Tempcon: Your Go-to Professional Industrial Chiller Maintenance Expert

It takes the right experience and expertise to inspect and maintain industrial chillers. Tempcon, with four decades of experience, is the right partner for chiller inspection and maintenance. Our trained technicians will follow a thorough checklist and cite the problems.

Contact us today to schedule your next chiller maintenance program with professionals.