Tempcon Chillers

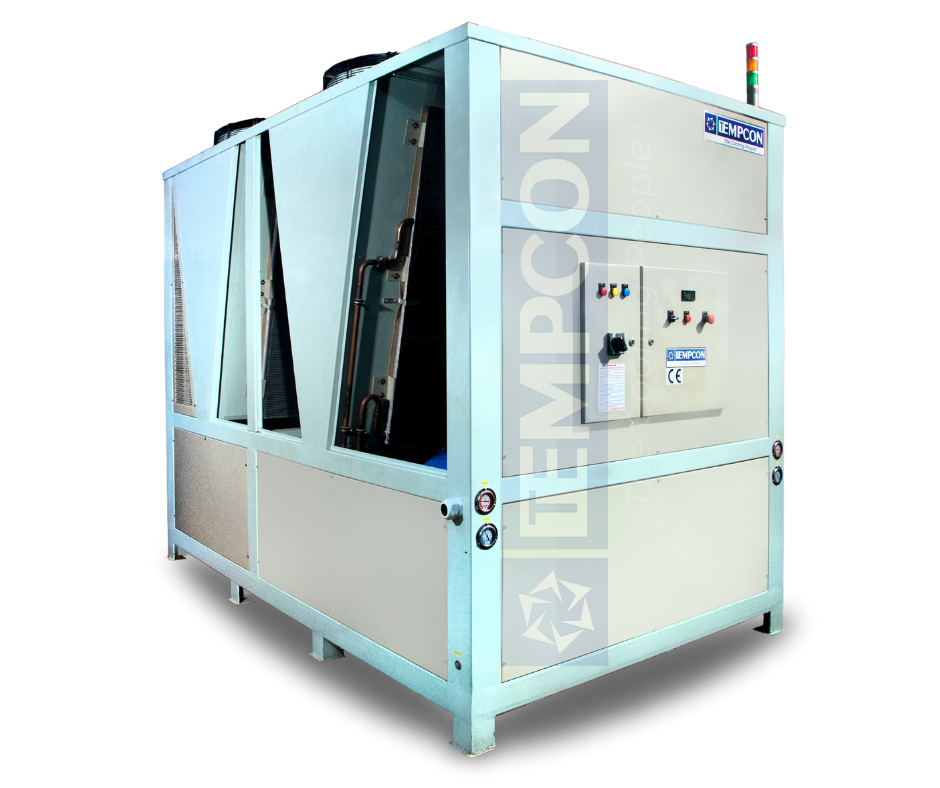

Buy Industrial Air Cooled Screw Chiller From Tempcon

Need high-efficiency heavy duty chillers? Opt for Tempcon air cooled screw chiller today! These chillers are built to handle heavy workload and continuous usage. Thanks to the screw compressor, Tempcon air cooled screw chillers can perform continuously with no need for cycling off. This leads to a greater energy efficiency.

Discover MoreWhat’s In There

Technical Specifications

Application Areas

Safety & Efficiency Guaranteed

Chillers usually have a defined suction and discharge temperature and pressure. Running outside this range can lead to inefficiency, excessive power consumption or damage. Tempcon screw chiller provides automatic adjustments to maintain safe operation within the envelop.

Why Choose Tempcon screw chillers?

Energy efficiency: reduces power consumption and improves COP

Reliability: Avoids frequent compressor start/stop and prolongs life span

Improved cooling performance: maintain stable cooling output

Lower maintenance cost: Reduces wear and tear due to excessive pressure or temperature

Smart Controls

Microprocessor-based smart control panel with a touchscreen with BMS / Modbus interface

Electronics expansion valve

EEVs modulate refrigerant flow dynamically based on load conditions allowing more accurate superheat control compared to thermal expansion valves.

FAQ

Tempcon air-cooled screw chillers operate within a temperature range of +4° to +25° Celsius. This temperature range befits a wide range of industries. All our chillers have smart control systems that operators can easily use to keep the temperature as per industry requirements.

These chillers use screw compressors that perform continuously without cycling off and reduce energy consumption by up to 30%. Our chillers also use variable frequency drives to further enhance efficiency by adjusting compressor speed based on cooling needs.

Yes, Tempcon chillers comply with the ECO design Directive by using eco-friendly refrigerants like R134a and R513A. These refrigerants have minimal impact on the ozone layer and follow the latest regulations.

Tempcon air-cooled screw chillers are engineered with proprietary noise reduction mechanisms to make them suitable for noise-sensitive environments. These chillers are ideal for unhindered commercial and industrial environments.

Our chillers are ideal for heavy-duty industrial processes, large server rooms, healthcare facilities, and other high-demand environments that require efficient cooling. Our chillers provide a constant and precise temperature within the set range.

The main components of air-cooled industrial screw chiller are

Compressor

Evaporator

Condenser

Expansion valve

Power panel

Control units

You must consider the following factors.

Energy rating

Refrigerant used

Certification of components

ISO certified manufacturer

Industrial environment

Proper load calculation

Type of chiller design

Our industrial air-cooled screw chillers offer a cooling capacity ranging from 40 to 500 TR.