Tempcon: Your Reliable Process Chiller Manufacturer In India

Get in touch with us to bring superior and precision process cooling solution for your industrial plant

Explore Our Industrial Chillers

Showing 1 – 8 of 8

Air-Cooled Scroll Chiller

- -40° To +25° Celsius

- Scroll Compressor

- 3TR To 80TR Output

- CE Certification

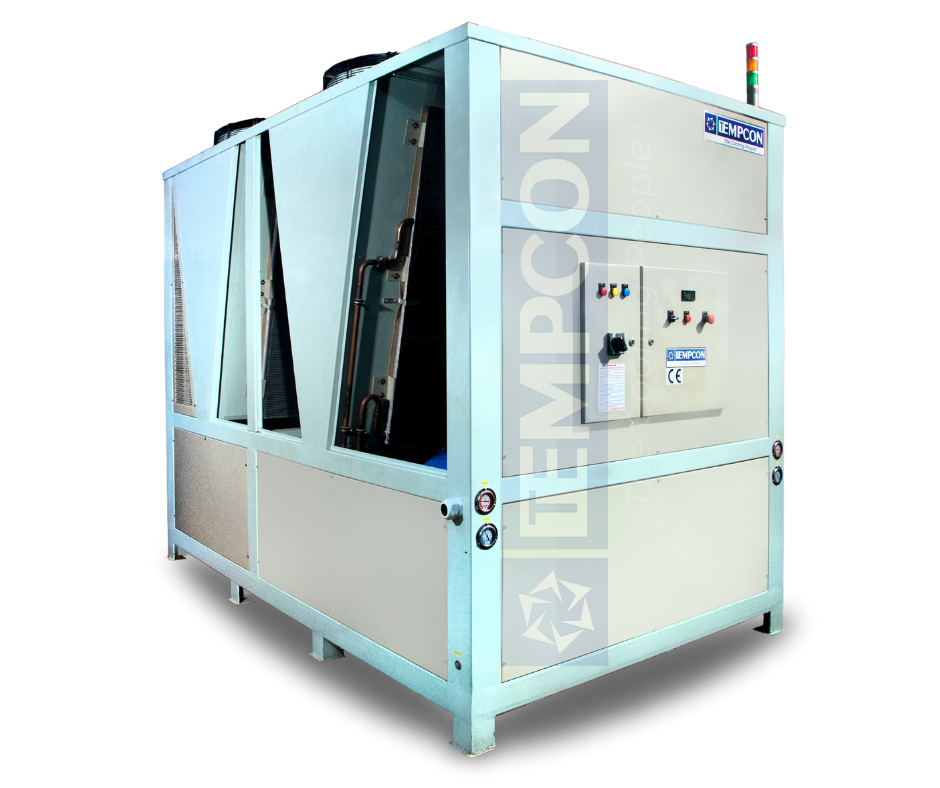

Air-Cooled Screw Chiller

- -40° To +25° Celsius

- Screw Compressor

- 50TR To 250TR

- CE Certification

Water-Cooled Scroll Chiller

- Scroll Compressors

- Shell & Tube Evaporator

- Stainless Steel Pump

- CE Certification

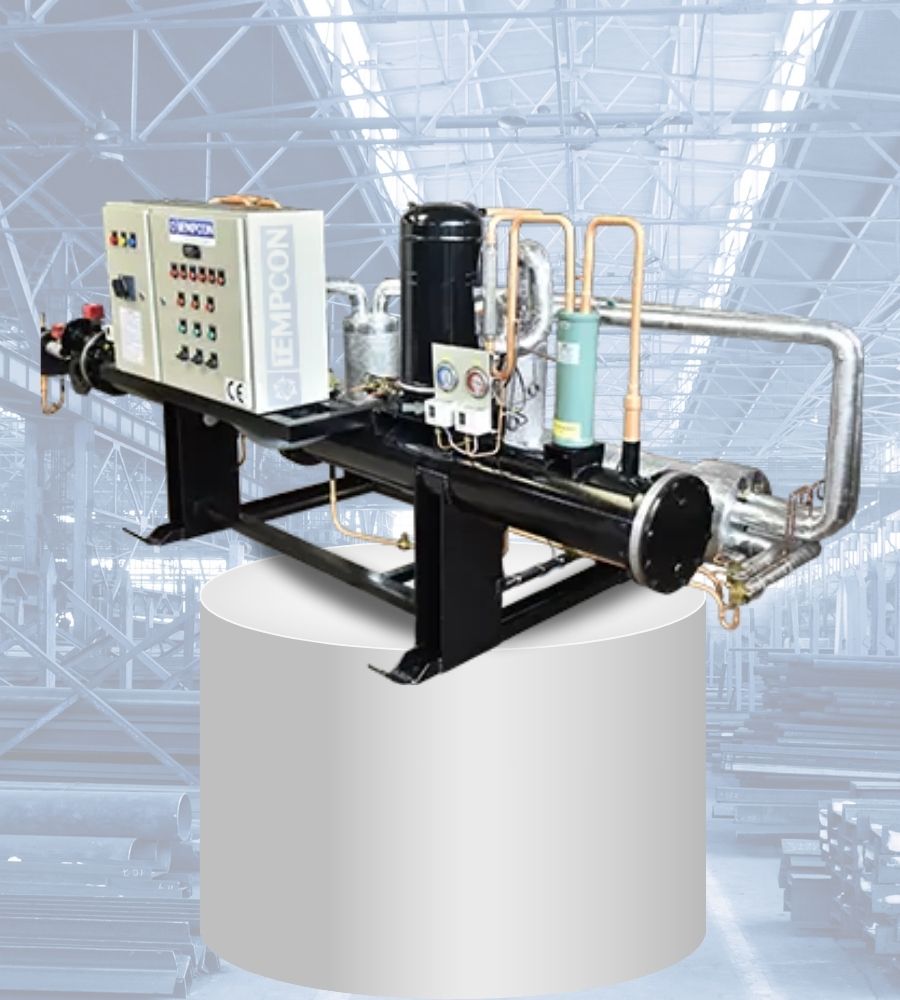

Water-Cooled Screw Chiller

- Semi-hermetic Screw Compressors

- Shell & Tube Evaporator

- R134a Refrigerant

- CE and PED Certified

Oil Chiller

- Scroll Compressor

- R407c Refrigerant

- Stainless Steel Tank

- Precise Temperature Control (±0.3°C)

Glycol and Brine Chiller

- Multiple Compressor Options

- Versatile Condenser Choices

- Stainless Steel Process Pump

- Precise Temperature Control (±0.3°C)

Reciprocating Chiller

- -40° To +4° Celsius

- Water / Air Cooled

- 1TR To 50TR

- CE Certification

VFD Chiller

- Scroll Compressors

- R410a Refrigerant

- EC Brushless Fans

- 10-100% Capacity Control

Technical Details of Our Chillers

Compressor Types

Refrigerant Types

Evaporator

Frame

The Most Energy Efficient Process Chiller Manufacturer In India

Your Pain Points | Our Solution

Tempcon has been manufacturing process chillers since 2006. We know the pain points of all the industries regarding the usage of industrial process chillers.

Say Goodbye To Sky High Energy Costs

With a microchannel condenser and electronic expansion valve, Tempcon manufactures highly energy efficient process chillers.

Say Hello To Sustainable Cooling

Make your processes sustainable with our range of eco-friendly cooling systems. Save water and energy and be the leader in sustainability.

Serving Businesses Across Major Industries

Guaranteed safety. Confidently buy from Tempcon

Safe outside. Safe inside. All major components are UL certified

Zero Defect Zero Effect Manufacturing paradigm followed

Eco

Hear From Our Clients

Good experience

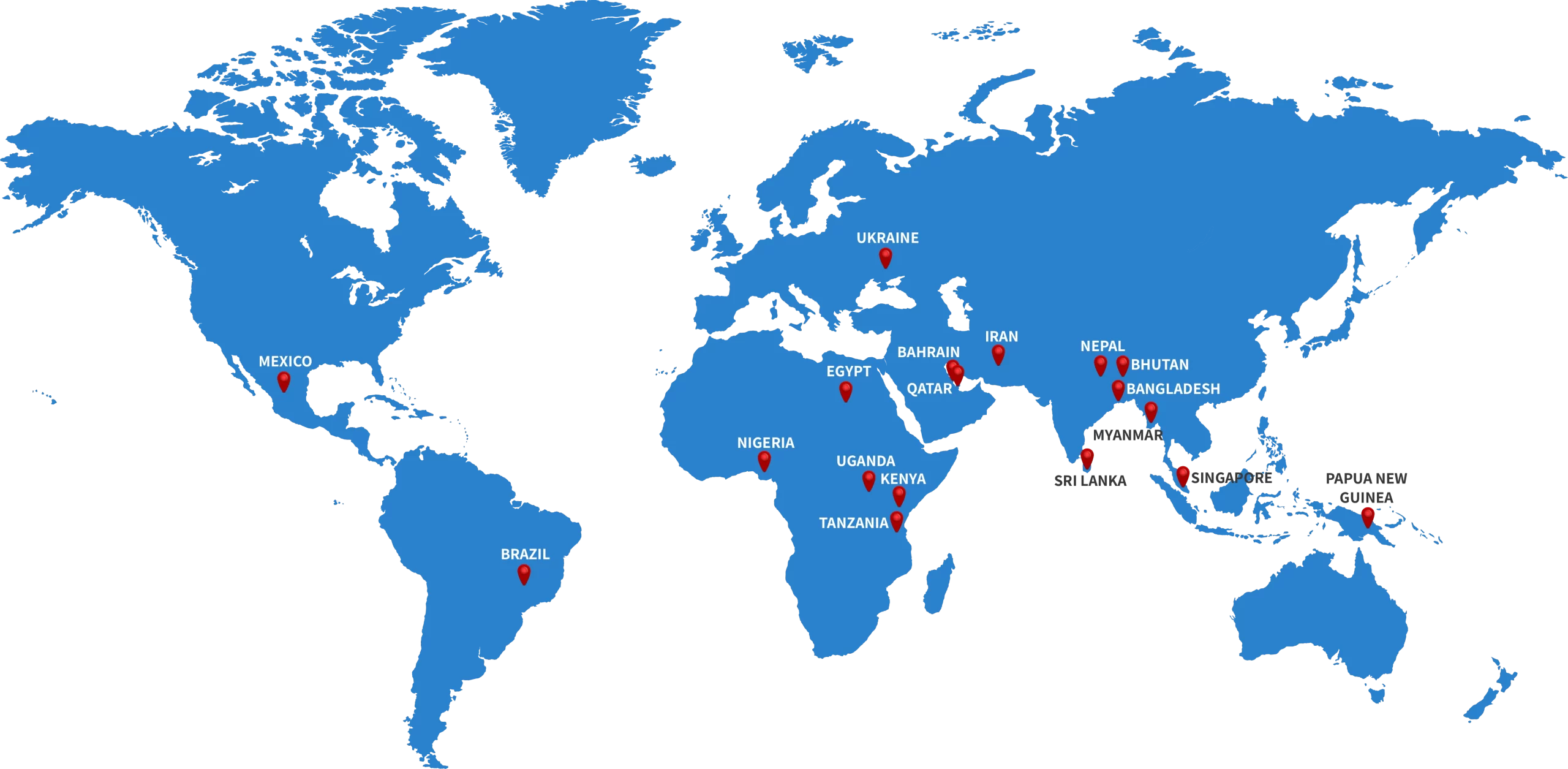

Serving Industries Across The Globe

The Tempcon Promise

Expert Team For Installation and Maintenance

Our chiller manufacturing excellence is complemented by our team of experienced maintenance engineers.

Regular maintenance? Sudden issue? We are just a phone call away. Our field engineers leave no stone unturned to prevent long downtime in your plant.

Call us

+91 33 24426216

+91 33 24422359

Ask Us Anything

As a chiller supplier with 40+ years of experience, we manufacture and supply water-cooled and air-cooled chillers – with option for either scroll or screw compressor. We also supply reciprocating and VFD chillers.

Yes, Tempcon is a reliable chiller manufacturer. We strictly adhere to environmental and safety norms set forth by the Indian government and EU authorities. All our chillers are CE certified – with major components being UL certified for enhanced protection. Head over to our Certificates to view our ISO and CE certificates.

Yes, every Tempcon cooling product comes with a comprehensive AMC. We provide both standard comprehensive AMC and ad hoc non-comprehensive AMC. Our contract guarantees four mandatory maintenance checks over a one-year period. Plant managers can rest assured that their process cooling system will keep on functioning with no rude shocks and unexpected downtime.

At Tempcon, we have two dedicated phone numbers for our clients to contact us specifically to request a service visit. You can find the phone numbers in the contact page. We are available 24/7 and our service engineers are present across the country to attend to your needs within hours.

Featured Blogs

Industry Insights

Chiller Efficiency Explained: Key Terms, Calculations and Factors

Chiller Inspection Checklist – What Do We Check When We Go For a Planned Maintenance Visit

The One-Stop Guide to Data Center Cooling: Keeping Your IT Infrastructure Chill

FAQ

Tempcon chillers follow the European Ecodesign Directive to ensure minimal emissions and energy consumption. We use eco-friendly refrigerants like RF10A, which have negligible ozone depletion potential to make them ideal for environmentally conscious industries in Guwahati.

Tempcon chillers are designed to handle Guwahati’s diverse climate—from humid monsoons to chilly winters and scorching summers. Our chillers ensure consistent cooling performance regardless of seasonal changes, making them dependable all year.

We are the most trusted industrial chiller manufacturer because:

- Regional expertise to understand industrial needs and tailor chiller designs as per Assam’s climatic conditions.

- Eco-friendly technology offering low-noise, low-emission, and high-efficiency chilling systems

- Dedicated pre and post-sales support from our in-house service team for hassle-free installation and maintenance.

We integrate advanced technology that maximizes energy efficiency while minimizing carbon footprints. Tempcon helps industries adopt greener practices by offering solutions that comply with global sustainability standards.

With over 18 years of expertise, we are pioneers in creating reliable, energy-efficient, and region-specific industrial chillers. We combine innovation with customer-centric services to meet your cooling needs.