Pharmaceutical technology and medical science are pillars of a healthier future and advancing healthcare.

The pharmaceutical manufacturing units give shape to the new formulations that are used to prevent and cure illnesses

The unit’s quality control depends on the indoor air quality and conditions maintained during every step of a pharmaceutical manufacturing process.

Industrial chillers maintain the optimal factors in pharmaceutical manufacturing units.

To understand the importance of industrial cooling systems, let us scout the vitality of temperature control in pharmaceutical manufacturing.

Role of Temperature and Humidity Control in Pharmaceutical Manufacturing

Preserving Product Quality and Stability

Temperature and humidity play a significant role in maintaining the quality of manufacturing outcomes in the pharmaceutical industry. Most ingredients used for manufacturing tablets, capsules, syrup, ointments, etc are highly sensitive.

Pharmaceutical manufacturing units need a stable environment to preserve quality and stop the degradation of active pharmaceutical ingredients (APIs). Proper temperature and humidity control will ensure product efficacy and potency of medications manufactured.

Compliance with Regulatory Standards

Statutory bodies like the WHO, FDA, and CDSCO mandate following certain industry standards to ensure safe drug manufacturing. These strict guidelines related to temperature and humidity should be followed for therapeutic efficacy.

Shelf Life Extension

Controlled temperature inside pharmaceutical and manufacturing units enhances the shelf lives of the raw materials and finished products.

No Contamination in Manufacturing Units

A controlled manufacturing unit is free from contaminants that can compromise the quality of manufactured drugs. So, enclosed manufacturing units require temperature control and air filtration.

All these parameters explain how important temperature control is for pharmaceutical manufacturing. Let us find out how industrial chillers help maintain regulatory standards and ensure optimum outputs of pharmaceutical manufacturing processes.

Applications of Industrial Chiller for Pharmaceutical Industry

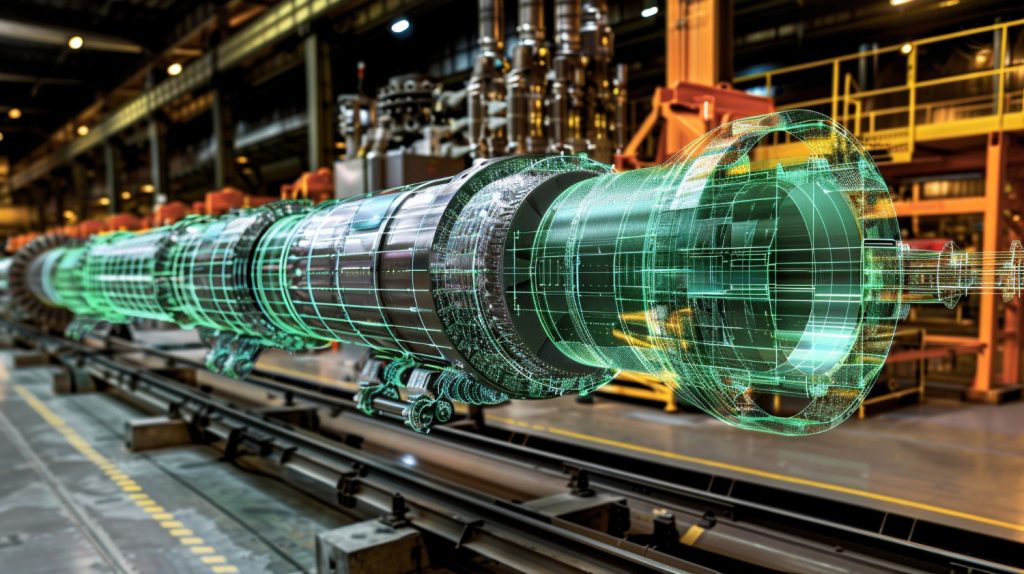

An industrial chiller for pharma is an engineered cooling system designed for cooling an entire manufacturing unit and maintains precise temperature control. Its prime function is to chill air by using a compressor system and maintain a required temperature level in production and storage units of a pharmaceutical manufacturing setup.

An industrial chiller for pharmaceutical manufacturing is applied for these purposes.

Process Cooling

Every machine or equipment generates heat when used. This heat accumulates inside a setup, enclosed to maintain air quality. Equipment like reactors, mixers, dryers, etc generate significant amounts of heat and may impart damage to the APIs. Hence, all the machines in a pharmaceutical manufacturing setup must remain within an optimum temperature range. Only industrial chillers can cool down these machines efficiently and avoid overheating.

Indoor Air Quality and Humidity Control

Pharmaceutical manufacturing is one of the most sensitive parts of this industry that must carry out its operations in a contamination-free environment. Modern industrial chiller manufacturers include air filters and easy-to-clean components in the latest chiller designs. Such chillers let filtered and chilled airflow inside a manufacturing unit. They also remove excess humidity from the indoor air and prevent microbial growth. These stable conditions ensure the contamination-free production of medicines.

Safe Storage and Transportation

As mentioned, most APIs are sensitive to temperature. Even the finished products need the proper environment for storage. This is why manufacturing units and warehouses of the pharmaceutical industry install industrial chillers. Controlled temperature increases products’ shelf life and enables proper storage and distribution.The output of pharmaceutical manufacturing is optimised only when the industrial chillers are picked after identifying the exact requirements.

Key Considerations for Choosing Industrial Chillers for Pharmaceuticals

Consider these parameters to make an informed decision while choosing the best industrial chiller manufacturer and its products.

- Cooling capacity: Industrial chillers must have the right capacity to handle specific cooling requirements of big pharmaceutical manufacturing units. Underpowered chillers will break down more often and cause temperature inconsistencies. Overpowered chillers will cost you more energy bills. An industrial chiller supplier for pharmaceutical manufacturing/industry will provide the cooling capacity and other specifications for the products available.

- Energy efficiency: Energy-efficient modern chillers can save on energy consumption without compromising cooling effects. Look for the best industrial chiller manufacturers with ISO and CE certification. Make sure their chillers are ECO-Design-friendly.

- Reliability and Redundancy: Always choose chiller manufacturers with a proven track record. It assures reliability and availability of resources to handle unseen downtimes. Such chiller manufacturers offer a complete solution to pharmaceutical manufacturing units.

- Maintenance and servicing: Always choose chiller manufacturers that offer maintenance and servicing along with installation services. They must offer original equipment parts for quick repair and reduce downtime.

- Industry standards and compliance: Make sure the chillers follow the latest industry standards and regulations to maintain product safety, efficacy, and quality.

Avoid your hassles by checking the certifications of an industrial chiller manufacturer. Follow these parameters to find out whether its chillers are worthy or not.

Ensure Quality with Tempcon’s Industrial Chillers for Pharmaceutical Manufacturing

Looking for the top industrial chiller manufacturer to get the ideal solutions? Look no further and get in touch with Tempcon. Our 40 years of experience and vast expertise will help you identify the best chiller solution. Ensure reliable temperature control and regulatory compliance with our latest industrial chillers for pharmaceutical manufacturing.